A sprayer's job is to distribute fluid over a designated area. No matter what type of sprayer at the center of the system is a pump. There are nearly endless different types of sprayers. They are built for several applications and require different types of pumps to deliver the flow characteristics necessary to complete those different spraying tasks.

At Dultmeier Sales, pumps are not just the center of a sprayer, they are at the center of our business. We sell, service, and support a wide variety of pumps for all types of sprayers. In addition, we prioritize understanding the different types, how they operate, and what pump works best on different sprayers.

In this guide, we will look at all the different types of pumps used on sprayers. We will examine how each pump operates and how they compare in terms of flow rate and pressure. In addition, we will offer real examples so you can see exactly how each pump is used. You'll be able to understand what type of sprayer pump will work for your application.

Different Types of Sprayer Pumps

While there are several variations of each type, the different pumps used on sprayers are centrifugal, roller, diaphragm, and piston pumps. Each pump is unique in its design and performance. Let's explore each type to understand how they operate and when to use them.

Centrifugal Pumps

- Pump Family: Centrifugal

- GPM Range: 0 to 500+

- PSI Range: 0 to 150

Centrifugal pumps use an impeller to move water or other fluids by using centrifugal force. They are known for their ability to move high volumes of liquid at relatively low pressure. The most common centrifugal pump type used on a sprayer is a straight centrifugal pump. Self-priming pumps can be used, but a straight centrifugal pump is typically more efficient and capable of developing higher operating pressure.

A self-priming pump is capped at about 40-60 PSI depending on the specific pump. The straight centrifugal pumps designed for use on sprayers can produce well over 100 PSI. They are intended to accommodate the high travel speeds of self-propelled sprayers combined with the expanded operating ranges of modern sprayer nozzles.

Common Centrifugal Sprayer Pump Applications

- Agricultural Spraying: Boom sprayers, fertilizer toolbars, boomless sprayers, fertilizer delivery on planters.

- Turf and Landscape: Golf course sprayers, sports field sprayers, large acreage sprayers.

- Industrial Uses: Salt brine trucks and trailers, water trucks for dust control.

Advantages of Centrifugal Sprayer Pumps

- High Volume Output: Centrifugal pumps can handle large volumes of liquid, making them suitable for applications requiring substantial flow rates.

- Durability: These pumps are robust and can handle abrasive and corrosive chemicals, making them versatile for various spraying tasks.

- Simplicity: The design is straightforward, which makes maintenance and troubleshooting easier compared to more complex pump types.

- Cost-Effective: Generally, centrifugal pumps are less expensive to manufacture and maintain, providing a cost-effective solution for many users.

Disadvantages of Centrifugal Sprayer Pumps

- Low pressure: Centrifugal sprayer pumps have lower pressure capabilities compared to some other types of pumps like piston or diaphragm pumps. While centrifugal pumps can move high volumes of liquid, they do so at relatively low pressures.

- Cannot Run Dry*: Running a centrifugal pump without fluid can cause significant damage to the pump. A centrifugal pump requires fluid in the pump case to lubricate the seal. *There are lubricated seals or "wet" seal centrifugal pumps that can run dry.

Centrifugal Pump Drive Types

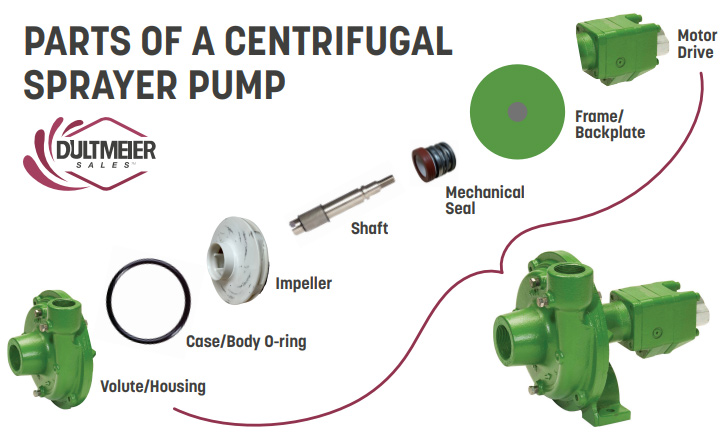

Parts of a Centrifugal Sprayer Pump

- Impeller: The heart of the pump, which is responsible for imparting kinetic energy to the liquid. The design and size of the impeller significantly affect the pump's performance.

- Casing: Encases the impeller and directs the flow of liquid. It also helps convert kinetic energy into pressure energy.

- Seal: Prevents leaks and maintains the pump's integrity by keeping the liquid within the system.

- Suction and Discharge Ports: Inlet and outlet points through which the liquid enters and exits the pump.

You can find a more detailed examination of centrifugal pump components and how they affect the performance of a pump in this guide to centrifugal pumps for fertilizer.

View All Centrifugal Pump Options

Roller Pumps

- Pump Family: Positive Displacement

- GPM Range: 2 to 60

- PSI Range: Up to 300

- Applications: Small and medium-sized boom sprayers, turf sprayers

Roller pumps use rollers inside a cylindrical housing to move liquid. As the rollers rotate, they create a vacuum that draws liquid in and then pushes it out. Roller pumps are very common on 3-point sprayers crop and turf boom sprayers, because they are self-priming, develop consistent pressure, and are less expensive compared to other types of sprayer pumps.

A roller pump is part of the positive displacement pump family. This means that a consistent volume of fluid is delivered with each cycle (in this case shaft revolution), regardless of the discharge head in the system. Simply put, you can spray at 60 psi if you want because the pump overcomes the restriction in the system. With a centrifugal pump, the system restriction will affect your operating pressure much more.

The larger roller pumps can produce about 50-60 GPM, limiting the size of the sprayer they can be used on. A roller pump can be repaired but the standard cast iron housings do have a limited life span. Friction eventually wears the pump housing to a point where the pump will no longer work efficiently.

To combat the wear and corrosion of agrochemicals and fertilizers, there are Ni-resist and Silvercast pump housings that last much longer than the standard cast iron roller pumps.

Advantages

- Pressure Output: Capable of producing consistent and generally higher pressure than a centrifugal pump.

- Self-Priming: Can draw liquid from a lower level, making them easy to start and use.

- Compact Design: Small and easy to integrate into different spraying systems.

- Can Be Reversed: Many roller pump models can be reversed so you can drive it either clockwise or counterclockwise. Consult the manual of your specific pump for details.

- Cost: Less expensive compared to other sprayer pump types. Especially when PTO driven since it does not require an engine or hydraulic motor.

Disadvantages

- Wear and Tear: Rollers wear out, especially when used with abrasive chemicals.

- Limited Flow Rate: Not suitable for applications requiring high flow rates.

- Maintenance: Regular maintenance is required to ensure optimal performance.

- Limited Lifespan: Wear and corrosion can increase the Internal clearance between the pump housing and rollers to the point that the pump no longer works effectively.

Drive Types

- PTO

- Belt Driven

- Electric Motor

- Gas-Engine

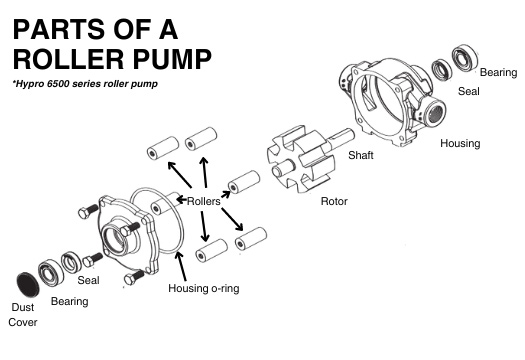

Parts of a Roller Pump

- Rollers: The moving parts inside the pump that create suction and discharge action.

- Rotor: Holds the rollers in place and drives their motion.

- Housing: Encases the rollers and rotor, providing a sealed environment for the liquid to move through.

- Shaft: Driven by PTO or motor and spins the rotor.

- Seals: Prevents leaks and maintains the integrity of the pump system.

Check out the Different Roller Pump Options

12-Volt Diaphragm Pumps

- Pump Type: Positive Displacement

- GPM Range: 1 to 5

- PSI Range: Up to 100+

- Applications: ATV/UTV sprayers, spot sprayers, small boom sprayers, low-volume chemical transfer

12-volt diaphragm pumps are very common and versatile. They are used on small sprayers because they are easy to power with a battery and relatively low in cost. These pumps work well with a wide variety of agrochemicals, cleaners, and other liquids, especially when diluted. They are self-priming, and they can run dry.

One standout benefit of the 12-volt sprayer pump is the demand switch. This feature shuts the motor off when you close a valve on the discharge side of the pump. When the valve is closed, the pressure increases, tripping the demand switch and shutting off the motor.

The most common application of this is when you are spot-spraying with a trigger wand or spray gun. When you pull the trigger, your pump turns on, when you release the trigger, the pump stops. This conserves your battery life and prolongs the life of the pump as it only runs when needed.

A 12-volt diaphragm pump can be used on smaller boom sprayers. However, they may only be able to work on booms with about 5-10 tips depending on the size of the nozzles that you use.

Advantages

- Portability: Lightweight and easy to transport, ideal for portable sprayer setups.

- Self-Priming: Can draw liquid from a lower level, making them easy to start and use.

- Low Power Consumption: Efficient operation with low electrical power requirements.

- Chemical Resistance: Can handle a variety of chemicals without damage.

- Demand Switch: The pump only runs "on demand", when you pull the trigger or open the valve to spray.

- Low-Cost: Very affordable compared to other pump types.

Disadvantages

- Limited Flow Rate: Maximum flow rates are about 5 GPM.

- Pressure Limitations: Maximum pressure is lower compared to other positive displacement pumps.

- Pump Life: The pump motor and other components do not have the same lifespan as other pump types. Parts can be replaced but the cost and time to repair may be nearly as much as a new pump.

Drive Types

- 12-volt Electric Motor

- This pump type is also available with 24-volt and 115-volt motors

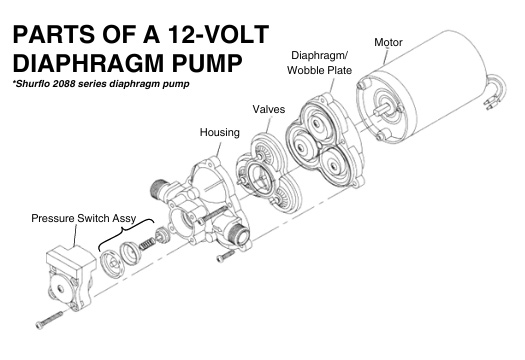

Parts of a 12V Diaphragm Sprayer Pump

- Diaphragm/Wobble Plate: This assembly is driven by the motor; it has an eccentric bearing that causes it to "wobble" and this motion creates the suction to pull liquid into the pump and force it out.

- Check Valves: let fluid flow into the pump and stop it from going back out of the inlet port.

- Pump Housing: Contains the wobble plate and check valve assembly, and serves as the pump chamber where the liquid is pulled into the pump and forced out.

- Motor: Powers the movement of the wobble plate.

Large Diaphragm Pumps

- Pump Type: Positive Displacement

- GPM Range: 3-100+

- PSI Range: Up to 725

- Applications: Tree spraying, turf sprayers, fertilizer applicators

Large diaphragm pumps use multiple diaphragms and chambers to move large volumes of liquid at high pressures. These pumps are the preferred tool for long-range or vertical spraying such as tree spraying. The combination of high-flow rate and high pressures, when combined with the right sprayer gun and nozzle, results in a stream of liquid that can be propelled 50 feet or more in the air.

Video of Diaphragm Pump on Skid Sprayer:

Diaphragm pumps can also be used on boom sprayers or fertilizer boom sprayers. While they don't offer the same flow rates as a centrifugal pump of similar size, they can be a good option for sprayers or applicators when the fluid being sprayed is too thick or viscous for a centrifugal pump.

Advantages

- High-Pressure Output: Capable of producing very high pressures

- Durability: The flexibility of the diaphragm offers good resistance to a wide range of abrasive and viscous fluids.

- Chemical Resistance: Can handle a variety of chemicals without damage.

Disadvantages

- Cost: More expensive to purchase and maintain compared to smaller pumps.

- Complexity: More complex design requires more safeguards and proper installation. Troubleshooting can be more complicated than with other pump types.

- Maintenance: The diaphragms and pump oil must be changed periodically, typically every 500 hours or 3 months of use.

Drive Types

- Engine Driven

- Hydraulic Driven

Parts of a Diaphragm Sprayer Pump

- Diaphragms: Multiple flexible membranes that move to create suction and discharge action.

- Check Valves: Control the flow of liquid into and out of the pump chambers.

- Pistons: Push and pull the diaphragms to create the necessary suction and discharge, driven by the crankshaft.

- Crankshaft: Driven by the engine or motor, rotation of the crankshaft drives the pistons

- Gear Box: Allows diaphragm pumps to be directly driven by a gas engine at about 3600 rpm.

- Regulator/Control: Serves as the relief valve and provides pressure adjustment. Also directs flow from the pump outlet to different sprayer features such as spray gun, agitation, etc.

View All Diaphragm Pump Options

Piston Pumps

- Pump Type: Positive Displacement

- GPM Range: Approx 1 to 68

- PSI Range: Up to 120

- Applications: Fertilizer application on toolbars or planters.

A piston pump is more common for fertilizer application than it is for pesticide/herbicide application. They do not offer the flow rates needed for large boom sprayers, and they are not as forgiving to solids or abrasion as diaphragm pumps. However, they excel at delivering fluid accurately and consistently.

This pump works by using pistons to create a reciprocating motion that draws liquid into the pump chamber on the suction stroke and then pushes it out on the discharge stroke. This mechanism allows the pump to generate consistent flow.

There are piston pumps that are designed for high pressures (1000 psi +), but the piston pumps used for agricultural applications are geared to precision. They are often ground-driven, which makes them the simplest option for automatic rate control. A ground-driven piston pump does not require flow meters or regulating valves for automatic rate control. As you speed up or slow down the pump delivers the precise amount needed to maintain your application rate.

These pumps are also available with hydraulic motors and PWM valves. This allows you to control the speed of the pump with a rate controller and flow meter.

Advantages

- Accuracy: The pump pushes a consistent amount of fluid with each stroke, especially important when applying fertilizers.

- Durability: Robust construction for long-lasting performance in harsh environments.

- Priming: Excellent ability to prime offers flexibility when mounting the pump on a sprayer, toolbar, or planter.

- Easy to Service: The NGP piston pumps are designed to be field repaired. The check valves can be quickly removed and cleaned or replaced as needed.

- Self-Adjusting: A ground-driven piston pump automatically adjusts to your speed, delivering the precise amount needed without flow meters or regulating valves.

Disadvantages

- Cost: More expensive than other pump types that deliver similar flow rates

- Complexity: More complex pumps with many components.

- No solids: Requires filter prior to the inlet to protect check valves and pistons from damage.

Drive Types

Parts of a Piston Sprayer Pump

The piston pumps used for fertilizer application are more complex pumps than some of the other fertilizer pumps. They feature several components but these are the main ones:

- Plunger: Reciprocating action of piston rod and plunger draws in liquid and pushes it out.

- Check Valves: Control the flow of liquid into and out of the cylinders.

- Crankcase: Houses connecting rod and crankshaft

See all the Piston Pump Drive Options Here

Key Takeaways

The type of pump used on a sprayer can have a drastic effect on the performance. Understanding the different types of sprayer pumps and their attributes will ensure you have the best tool for your application. The Dultmeier Sales team has decades of experience and can provide you with insights and guidance in selecting and troubleshooting your sprayer pump.

Tech Ag & Industrial Sales

Shane Blomendahl is a tech sales veteran at Dultmeier Sales with over 10+ years of experience in liquid handling products covering several industries and applications.